Electronic Seal System

At MIT we believe that inspired technology should be used to assist you, the transporter, in managing your wet stock. E-lock was designed and manufactured with this in mind offering you a cost-effective solution to monitor wet stock from loading to delivery.

Why Should you invest in our product?

E-lock is one of the most innovative ways to reduce the risk of unauthorized product movement on sealed parcel delivery (SPD) systems by allowing you to have a useful tool to fully control your entire logistics chain with a user-friendly system.

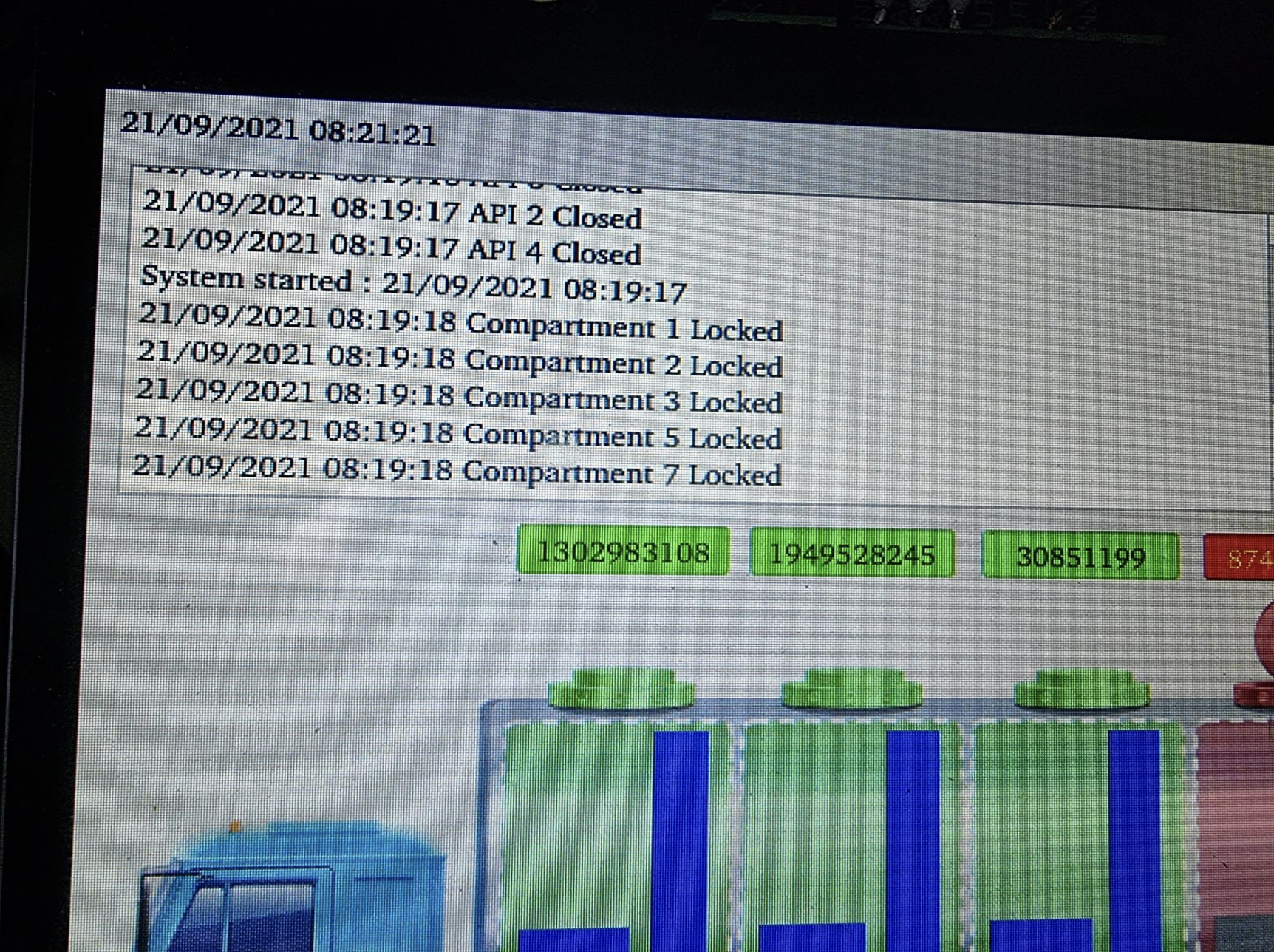

E-lock will seal the compartment after loading, and it will remain sealed until the delivery is made without driver interaction. The product cannot be manipulated during transport. Real time event logs, location, geo-fencing, and mapping as well as historical data with filter options is at your fingertips with this user-friendly system.

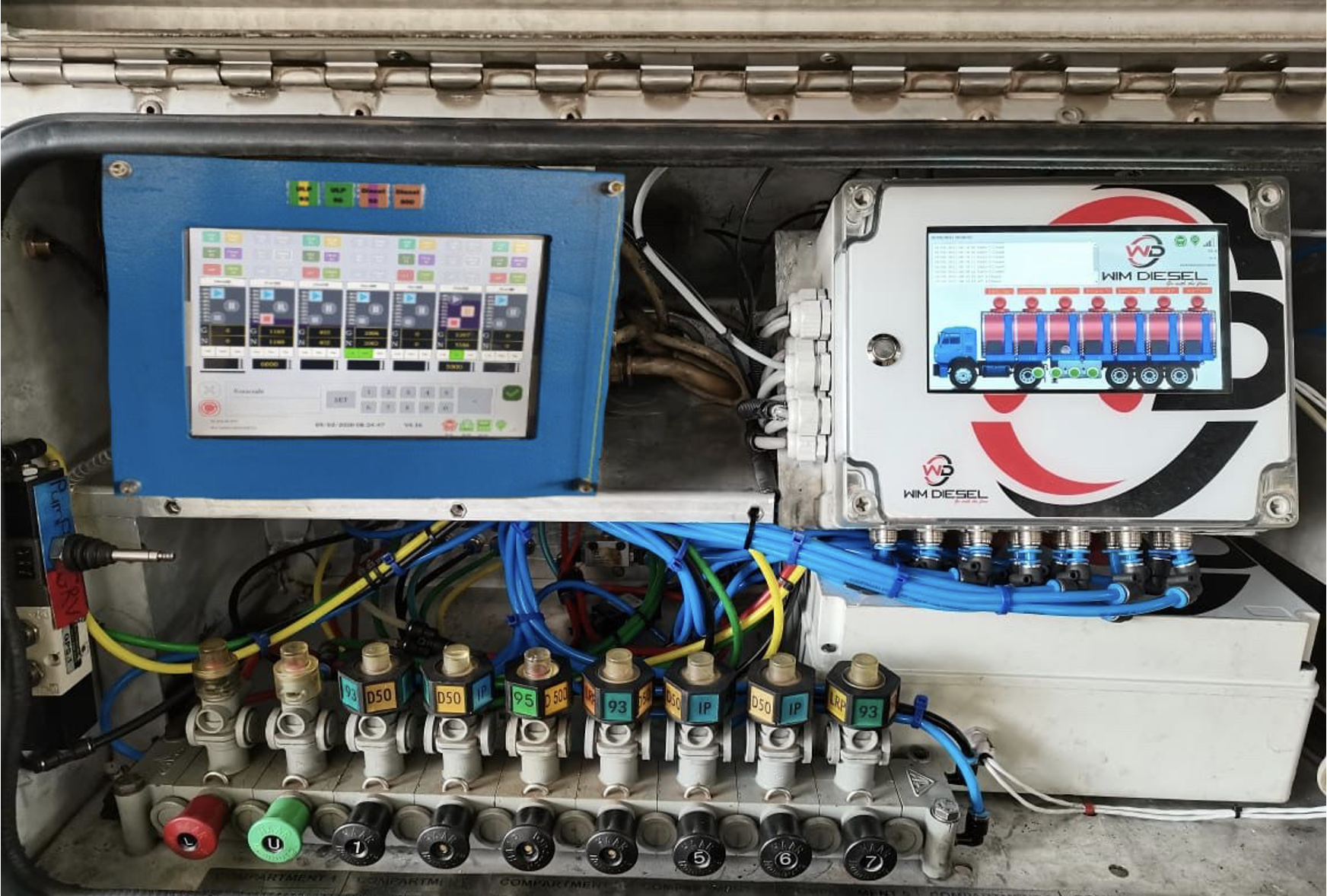

E-lock can use a variety of sensors on the tanker such as manlid cover sensors, API sensors, bottom valve sensors to detect and evaluate additional information about activities on the tankers. E-lock can be upgraded to a crossover prevention system and overfill protection system in an easy and cost-efficient way.

What does MIT’s Electronic Seal System offer you?

Real time event logs of seal status

Monitoring of manlid dome covers, bottom valves, and API adaptors

E-lock can be installed as a stand-alone system or as part of an ETLG system

Onboard printing of seal status

All sensor movement is recorded even after the seal is broken

Self-sealing once loaded, no driver interaction required

Full colour display screen to easily identify seal status

Wetleg sensors are optional for the identification of product retention / left onboard (LOB)

Ultra-sonic probes are optional for product levels for stand-alone systems

After Care Services

- Servicing and preventative maintenance can be co-ordinated to slot in with the customer's service schedule

- We offer two verification centers located in JHB and DBN

- Breakdowns will be handled telephonically and this support is available 24 hours a day, 7 days a week

- Should a technician be required to attend to a vehicle, they will be dispatched from the nearest verification center

- Warranties are carried out and conducted from these two centers

- MIT has a 1 year warranty

- MIT boards and components are manufactured and repaired by us and not imported therefore parts are readily available.

Gallery

Contact us today!

Electronic Seal System page form

We will get back to you as soon as possible

Please try again later

ABOUT US

Our innovative and high-tech solutions help you secure your load against theft, save time, reduce waste and keep your products safe. We can reassure you will know where every drop of your products goes.

PRODUCTS

All Rights Reserved | Measure It | Privacy Policy